Interlock Type-A Conduit with Double Wire

Semi-Interlock Double Spring Tube (SAWSP)

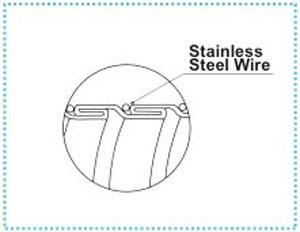

Stainless steel wire is inserted into the spiral valley of the Interlock Type A Conduit (Semi-Inter Tube) to create a larger bending radius. Excellent pliability and withstands repeated bending.

Features and Attributes:

- The doubling of the stainless steel wire produces a stable outer diameter. The increased stability results in no elasticity, and can provide optimum protection for optical fibers. Especially for laser fibers, quartz-type optical fibers, hollow optical fibers, etc.

- Stainless steel wire is inserted into the spiral valley of the Interlock Type A Conduit to create a larger bending radius. (Refer to figure 1 in Technical Specs.)

- It is also possible to modify the bending radius by changing the wire diameter and rod.

- Excellent pliability.

- Withstands repeated bending.

- RoHS Compliant

Standard Product:

- Flexible Tube Material: Stainless Steel (SUS304), Aluminum (Optional)

- Spring Material: Stainless Steel (SUS304), Aluminum (Optional)

- Sheathing Variety: Glossy Soft Polyvinyl-Chloride (PVC), Polyethylene (LDPE , HDPE), Polyurethane (TPU), Polyolefin (PO). More options are available, please view Customizations

- Length: Maximum continuous length is 10 meters. However tubes can be joined to make a maximum of 30 meters in length. Please contact us for details.

- All customizations outside of the standard listed above, will be custom and made to order. Please view Customizations for a full listing of available options.

Services Available Upon Request:

- Double Washing: Double washing treatment (using detergent) can be applied to tubes for high precision applications.

- Chemical Polishing: We offer tubes with chemical polishing, which provides extra shine for optical applications. (Special polishing for semiconductor-quality applications also available.)

Common Applications:

- Protection of optical fiber for dental lasers

- Protection of optical fiber for high-power lasers and welding machines

Stock Level: Non-stock made to order item. General lead time is 4-6 weeks.

Figure 1

|

Standard type |

PVC coating type |

||||||||||||

|

Model (Part Number) |

ID |

OD |

Bending |

Max Length one stretch (m) |

Approx Weight |

MOQ (m) |

Stock |

Model (Part Number) |

OD |

Std. Length (m) |

Approx |

Max Length one stretch (m) |

Stock |

|

SAWSP-3.2N |

3.2 (0.126) |

5.2 (0.205) |

60 |

10 |

67 |

30 |

Contact Us |

SAWSPP-3.2N |

6.5 (0.256) |

100 |

99 |

10 |

Contact Us |

|

SAWSP-4N |

4.0 (0.157) |

6.0 (0.236) |

70 |

10 |

70 |

30 |

Contact Us |

SAWSPP-4N |

7.0 (0.276) |

30 |

103 |

10 |

Contact Us |

|

SAWSP-4.5N |

4.5 (0.177) |

6.5 (0.256) |

80 |

10 |

72 |

30 |

Contact Us |

SAWSPP-4.5N |

7.7 (0.303) |

30 |

106 |

10 |

Contact Us |

|

SAWSP-5N |

5.0 (0.197) |

7.0 (0.276) |

80 |

10 |

74 |

30 |

Contact Us |

SAWSPP-5N |

8.6 (0.339) |

30 |

109 |

10 |

Contact Us |

|

SAWSP-6N |

6.0 (0.236) |

8.0 (0.315) |

110 |

10 |

77 |

30 |

Contact Us |

SAWSPP-6N |

9.6 (0.378) |

30 |

113 |

10 |

Contact Us |

|

SAWSP-7N |

7.0 (0.276) |

9.3 (0.366) |

115 |

10 |

80 |

30 |

Contact Us |

SAWSPP-7N |

11.0 (0.433) |

30 |

118 |

10 |

Contact Us |

|

SAWSP-8N |

8.0 (0.315) |

10.2 (0.402) |

115 |

10 |

83 |

30 |

Contact Us |

SAWSPP-8N |

12.0 (0.472) |

30 |

122 |

10 |

Contact Us |

|

SAWSP-9N |

9.5 (0.374) |

12.2 (0.480) |

120 |

10 |

86 |

30 |

Contact Us |

SAWSPP-9N |

14.0 (0.551) |

30 |

126 |

10 |

Contact Us |

|

SAWSP-10N |

10.0 (0.394) |

13.0 (0.512) |

150 |

10 |

90 |

30 |

Contact Us |

SAWSPP-10N |

15.4 (0.606) |

30 |

132 |

10 |

Contact Us |

|

SAWSP-11N |

11.0 (0.433) |

14.2 (0.559) |

300 |

10 |

Please ask |

30 |

Contact Us |

SAWSPP-11N |

16.5 (0.650) |

30 |

Please ask |

Contact Us |

|

|

SAWSP-13N |

13.0 (0.512(1/2″)) |

16.0 (0.630(5/8″)) |

Contact us |

10 |

Please ask |

30 |

Contact Us |

||||||

|

SAWSP-16N |

16.0 (0.630(5/8″)) |

18.7 (0.736) |

Contact us |

10 |

Please ask |

30 |

Contact Us |

||||||

Below are the general available options for customization. Please be advised that there may be restrictions based upon size, and application for usage. Please Contact Us for support on your customization requirements!

Optional Material for Wire: Aluminum

Available Flexible Metal Tube Materials:

| Material | Grade |

Application |

Features | Applicable Tube Type |

| Stainless Steel | – SUS304 (Standard) – SUS303 – SUS316 – SUS430 |

– General Industrial – Medicinal |

– Rigid – Does not Rust |

– Most tube type |

| Aluminum | – General Industrial – Medicinal |

– Does not Rust – Anti-Static – Lightweight but Less Sturdy – Excellent Thermal Conduction |

– Square Lock A – Interlock Type B – Screw Tube |

|

| Titanium | – General Industrial – Medicinal – Space Engineering |

– Rigid – Anti-Static – Lighter than Stainless Steel |

– Square Lock A | |

| Bronze Phosphate | – C5341 | – Noise Counter-Measure | – Electromagnetic Compatibility (EMC) | – Most tube type |

| Copper | – Noise Counter-Measure | – Electromagnetic Compatibility (EMC) | – Most tube type | |

| Brass | – Noise Counter-Measure | – Electromagnetic Compatibility (EMC) | – Most tube type | |

| Steel | – Galvanized Steel Strip – SK Material (Hardest Steel) |

– General Industrial | – Affordable Price – Heavy – Rusty – Generally Needs to be Sheathed |

– Most tube type |

Sheathing Materials and Information

Adding a resin/rubber coating to a flexible tube provides the following additional benefits:

– Waterproof/resistant

– Oil-proof/resistant

– Attractive appearance

– Additional strength

– Superior insulation

**The following chart displays the most common materials available. Please consult us regarding specifications, minimum lot, delivery date, sheathing combinations, and additional materials available (including any heat or chemical resistance requirements).

| Material Type (Code) | Characteristic | Color | Resin Feature | Surface Appearance |

| PVC/Polyvinyl Chloride (P) | Soft | Black (Standard), Gray, White, Ivory, Red, Pink, Orange, Yellow, Yellow-Green, Green, Blue, Clear | – Pliable – Chemical Resistant – Heat Resistant up to 60°C – High Oil Resistance |

– Glossy – Matte – Clear |

| Semi rigid | Black | – Slightly Hard – Smooth Surface – Chemical Resistant – Heat Resistant up to 60°C – Oil Resistant |

– Glossy | |

| Flame Resistant | Black, Gray, White, Red, Pink, Orange, Yellow, Green, Blue | – Pliable – Chemical Resistant – Heat Resistant up to 60°C – High Oil Resistance |

– Glossy | |

| Flame Resistant, UL Standard | Black | – Pliable – Chemical Resistant – Heat Resistant up to 105°C – High Oil Resistance |

– Matte | |

| Polyethylene (PE) | Low density (LDPE) | Black | – Harder than the Soft Hard Type – Smooth Surface – Chemical Resistant – Heat Resistant up to 70°C – High Oil Resistance |

– Glossy |

| Polyester Elastomer (TEEE) |

We can provide soft(ShoreA90) to Semi rigid(ShoreD72) | Black Opaque | – Pliable – Weatherproof – Heat Resistance up to 120°C |

– Glossy |

| Silicone Rubber (Si) | Soft | Black, Gray | – Pliable – Heat Resistance up to 180°C |

– Matte |

| Fluorocarbon Resin (FEP) (ETFE) (PFA) |

Flame Resistant | Black | – Less Pliable – Excellent Chemical and Oil Resistance – Slippery Non-Stick Surface – Heat Resistant up to 220°C |

– Glossy |

| Polyurethane (PU) | Ester Grade | Black | – Pliable – Abrasion Resistant – Heat Resistant up to 70°C |

– Glossy |

| Ether Grade | Black, Ivory | – Pliable – Abrasion Resistant – Water Soluble – Heat Resistant up to 70°C |

– Glossy | |

| Olefin Elastomer (O) | Soft | Black | – Pliable – Weatherproof – Heat Resistant up to 60°C |

– Matte |

PVC Sheathing Varieties

| Figure Num. | Sheathing Variety | Part Number Code | Features |

| 1 | Tight-Fitting | KSP- __N | – Standard item – PVC fills the spiral valley to make the finished surface even and smooth. |

| 2 | Vacuum Sheathing | KSP-__N-B | – During processing, sheathing is applied in a vacuum. – The finished surface maintains the spiral pattern of the coil. |

| 3 | Bagging Sheathing | KSP-__N-F | – Sheathing is applied only on the surface of the tube and the spiral valley contains no PVC. The surface of the sheathing will be completely smooth. |

| N/A | Heat Shrink Sheathing | KSP-__N + Shrink tube type# | – Please contact us for more details. |

Other Services

Double Washing and Chemical Polishing

Double washing:

Double washing treatment (using detergent) can be applied to tubes for high precision applications.

Chemical polishing:

We offer tubes with chemical polishing, providing extra shine for optical applications.

※ Special polishing for semiconductor-quality applications also available.

Instructions on How to Measure Bend Radius: PDF Here